Food Safety – It Concerns All of Us!

Consumers globally are increasingly becoming concerned about food safety issues as cases of lifestyle-related and food-borne diseases surge.

The concerns by consumers has pushed governments and food industry stakeholders to come up with stringent food regulations regarding food safety and quality of end products to reduce food-related health issues and improve operational excellence for businesses playing diverse roles in the farm-to-fork value chain.

As part of creating awareness and building knowledge around food safety, the International Association of Operative Millers Mideast & Africa (IAOM – MEA) in partnership with Cereal Millers Association of Kenya and the African Milling School staged a three-day food safety training course on October 18 to 20, 2018. The training was held in the facilities of the African Milling School, Nairobi, Kenya.

Understanding the complexity of food safety.

The training gave an opportunity to plant managers, production managers, millers, heads millers and quality control managers to evaluate and learn more about food safety essentials, challenges and concerns on safety, hazards and their control, food safety management, prerequisites for achieving safe food production and measures necessary to comply with private, national and international regulations and legislation on food safety.

It emerged during the training that food safety issues cut across countries globally as previous health compromising incidents related to foods demonstrated. This exerts pressure on food producers to take responsibility in ensuring what consumers eat is safe.

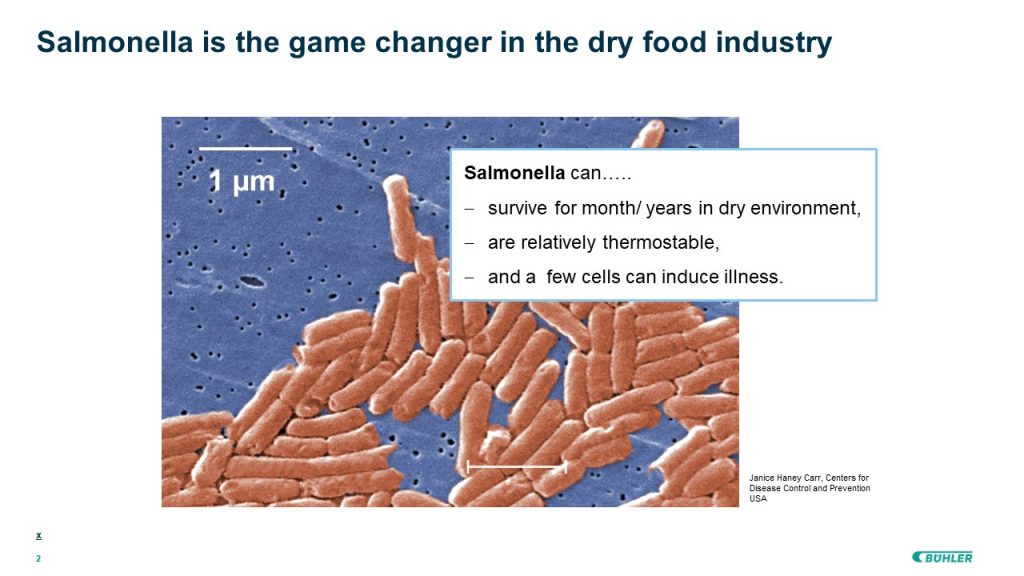

Food safety issues can be caused by various contaminants that are biological, chemical or physical in nature. These include pathogenic bacteria such as Salmonella, viruses such as norovirus, parasites, pests, mycotoxin or foreign matter such as glass, metal, plastic or wood.

For example, one of the deadliest food poisoning outbreaks was linked to aflatoxin in maize in 2004 affecting 317 people in Kenya, with 125 of them succumbing to the intoxication. Still today, millions of people across Africa are exposed to aflatoxin and other mycotoxins which increases the risk of child stunting and liver cancer. Another widespread food safety hazard discussed during the training is the presence of salmonella in ready to eat food. A well-documented case of Salmonella chocolate led to a recall of nearly a million chocolate bars with the manufacturer making a loss of £20 million.

“The health of consumers/people is our main concern,” Martin Schlauri, Managing Director of the Africa Milling School told participants drawn from the MEA region.

Participants who turned up for the training heard how food safety contamination can occur through different sources such as wrong dosing of micronutrients during the food processing phase as it happened in Brazil in 2007, or can also come from the environment such as a previous case of China where high levels of calcium arsenic/lead was found in rice. The contaminant could also be linked to food contact materials such as it happened in 2005 in Europe were baby milk released to the market was recalled due to chemical contamination by packaging material.

Food contamination can also be a result of machine failure such as the 2012 incident in the USA where 2.8 million of cereal boxes were recalled from the market due to possible presence of metal pieces.

Aim of food safety training.

The food safety training by IAOM – MEA is also meant to create awareness not only on the safety requirements but also on the importance of making reference and complying with legislative provisions for the industry.

As a key stakeholder in the food industry, IAOM – MEA believes its members are part of a team in the farm-to-fork value chain that should be responsible for the safety of the food they produce and by providing the training they can “build knowledge around food safety, leverage food safety as a competitive advantage and reduce risk and liabilities.”

The food safety training did not only provide a forum for participants to share their experience and connect to the food safety community but also was a good opportunity to learn how to develop and implement an action plan for their milling plants. “Food safety for food producers means being responsible for the food you produce,” said Marco Lechner, Food technologist and Food Safety expert of Buhler AG, Uzwil, Switzerland.

The food safety requirements could be looked at from different perspectives such as the norms and national standards of any country, private standards that guide production by many food companies, customers’ expectations and also Code of Practice where it exists.

“You cannot blame others for food contamination as the food law says: You’re guilty unless proven otherwise,” said Lechner.

The training emphasized that food has to be safe also for the more vulnerable population such as the Young, Old, Pregnant, Immunosuppressed and (Food) Sensitive people, which are also known as YOPIS.

Food safety along the value chain.

Participants discussed how best to implement a food safety regime at various levels of the value chain starting with awareness among farmers, traders, agro-food converters, food processors, retailers and consumers on the nature, severity and extent of food safety problems today.

Furthermore, an effective food safety regime requires knowledge of national and international food industry regulations and their impact on the value chain.

For example in Nigeria, the government in 2014 unveiled the National Policy on Food Safety and Implementation Strategy “to meet the needs of the country in adopting and implementing a modern and effective National Food Safety System.”

In addition, food processors and supervisors of food processing operations require skills or knowledge of food safety and hygiene in all facets of food handling.

Some the governments may require that those people working in any level of food processing operation to have specified skills and knowledge.

Again drawing from the Nigerian example, in December 2017 the government gazetted the country’s regulations for the feed milling industry which among other requirements is the employment by every milling plant a registered animal scientist as a technical officer to supervise the operation of the feed milling plant.

Moreover, the IAOM – MEA training emphasized the importance of measurements in the implementation of food safety policies especially during the storage and processing of food products.

Food safety standards and regulations.

Across the global food industry value chain there are various national and international standards that have been approved for use by food producers such as the International Featured Standards (IFS), which is a global safety and quality standards, British Retail Consortium (BRC) and the Global Food Safety Initiative (GSFI).

Enforcement of these standards and others by milling operations requires embracing the Hazard Analysis Critical Control Points (HACCP) systems along the entire production process for easy identification, monitoring and prevention of food safety hazards that can compromise quality of the food products.

“HACCP is the tool to identify risks in your process and decide on actions and measures,” Lechner told participants during the food safety training.

HACCP as prevention-based food safety system would enable millers for example to identifying contamination risks, monitor and document process steps and critical plant parameters to avoid liability cases.

A further key standard to ensure food safety is the Good Manufacturing Practice (GMP). It sets the basic requirements for food production and helps milling plant designers and operators to define hygienic zoning of your processing facility to avoid contamination. For example according to the Nigeria feed milling regulations “every feed mill shall be located not less than 200 metres from a livestock area of the farm in case of on-farm mill.”

Allergens.

During the IAOM – MEA food safety training in Nairobi, the plant managers, production managers, millers, head millers and quality control managers in attendance discussed the importance of understanding allergens in food and how to handle allergens in food.

With the number of people who are allergic to some food components increasing, the awareness about the allergens especially through the media is also increasing. Although allergens are not toxic, they cause some people to overreact and can lead to serious health issues.

“Allergens are defined by the food law and comprise products such as milk, eggs, fish, tree nuts, peanuts, wheat and soy, which food producers need to declare on the label of consumer products by law,” Lechner said.

Due to the limited availability of raw materials, for most millers in the MEA region, the procuring quality of wheat or maize (corn) is a challenge. The cleaning with new technologies such as color sorters SORTEX, enables grain millers to eliminate contamination such as ergot, foreign material and other impurities in wheat.

The food safety training was an eye opener for the participants particularly on the problematic mycotoxins occurrence along the farm-to-fork value chain.

“Mycotoxins, in particular aflatoxin, are produced by specific moulds of Aspergillus flavus and parasiticus,” said Schlauri.

“The factors which contribute to mould growth is high ambient temperature, moisture, drought, mechanical injury, insect and plant varieties, which means high aflatoxin risk” he said.

According to Schlauri “the contamination cycle of mycotoxins from food to feed through heavily contaminated by-products that end up in animal food products like milk needs to be interrupted.”

Finally, participants discussed the challenge of microorganisms in food contamination and specifically the conditions under which they thrive such as nutrients, moisture, ideal temperature and optimum pH level.

The food safety course outlined how food processors along the value chain should create an environment that suppresses the development of micro-organisms. “Bacteria move with a “carrier” which can be water, air or utilities. The bran of a wheat kernel is more contaminated than the endosperm,” said Schlauri.

“Thus the challenge of high micro count contamination and consequent poor shelf life is more on common for whole meal or brown bread” he said.

Dangerous bacteria include Salmonella and pathogenic E-coli and as such must be completely absent in food to protect consumers.

“Salmonella can be controlled by appropriate testing of incoming raw material, pest control and avoiding birds (pigeons) to access the intake area of grain,” added Schlauri.

Food safety training – a real benefit for the participants.

The participants at the food safety training weighed in on the importance of the program and how the course impacted on their perception of their role and that of their enterprises in ensuring safety of consumers and riding on quality as the basis for competition within the industry.

“Food safety is not a program but it is an attitude,” said Emmanuel Mazimpaka of Bakhresa Group, a grain milling company in Rwanda.

For Solomon Mutiso of United Millers, Kenya: “The value chain is where every one of us has a role to play in order to achieve food safety and security.”

“Air management – I think this has made me know the main reason why mould occurs in the milling machines especially the roller mills and sifters as well as the finished product silos,” said Bernard Kisalia also from United Millers.

“Food safety was a useful subject, it builds trust between the consumers and manufacturers. Milling process should be well performed so as to produce safe products for human consumption,” said Agneta Mbithe, from Mombasa Maize Millers in Kenya.